With more than 50 years of experience and expertise, Norca Precision is the trusted provider of gear shafts and gearing solutions to OEMs across a variety of industries.

From custom-designed precision gearing solutions to large quantity production runs for OEMs, Norca Precision solves the toughest gearing challenges. Our unparalleled product quality and responsiveness, combined with design and manufacturing expertise, make us a go-to partner for leading OEMs. We are committed to making gears and gear shafts that meet customer needs and solve gear challenges—right the first time, on time, every time.

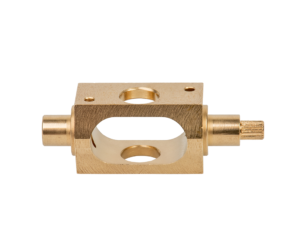

Some of Our Gear Shaft Solutions

High-Precision Gear Shafts

Norca has the ability to create a wide range of high-precision gear shafts, miniature gear shafts and gear assemblies. Our advanced Swiss turning methods and manufacturing techniques make Norca the trusted design and manufacturing partner for leading OEMs. Our gear shafts are used in a variety of safety-critical applications, from medical and dental equipment to laboratory equipment and industrial controls.

Custom Gear Shaft Solutions for Specialized Industries

We produce a wide range of gear shaft solutions, including miniature gear shaft assemblies and high-precision gear shafts. The parts we produce are used in safety-critical applications, from dental equipment to fuel injection pumps. Some of the gear shaft solutions we manufacture are:

- Miniature Gear Shafts: We develop miniature gear shafts for use in a variety of instruments, including avionics instruments

- Small Gear Shafts and Gears: We develop small size gear shafts for use in Gear boxes, Meters, Sprinklers and more.

- Diesel-Motor Fuel Injection Pumps: Our gears are used in diesel-motor fuel injection pumps, including distributor injection pumps and in-line fuel injection pumps.

- Dental Equipment: Our miniature gears and gear shafts are found in dental instruments, including prophy angle deices.

- Aircraft: Our fine precision fine pitch gearing solutions can be found in aircraft around the world.

Versatile Materials, Custom-Made

Norca Precision miniature gear shafts and gear assemblies are made from a variety of materials, including, but not limited to, plastics, brass, iron, aluminum, stainless steel, and carbon steel for high-strength and high-temperature properties. We can produce large-quantity runs or custom-make parts from customer drawings. Whatever your specifications, our team of design engineers will develop the right solution to meet your needs.

We are experts in gear shaft manufacturing, providing OEMs with high-quality, reliable gear shafts to leading OEMs for the past 50 years. Our precision machined gear shafts come in a wide range of diameters, from miniature gear shafts to larger gear shafts.

Here are some of gear shafts and miniature gear shafts we have designed and manufactured recently:

What are Gear Shafts?

Gear shafts are a critical component of gear assemblies. Gears shafts attach to a toothed wheel (the gear) or a rack and rotate it so it can engage and turn another gear. Gear shafts come in varying lengths and diameters and can rotate gears at a wide range of speeds. A typical mechanical device might employ multiple gear shafts and gears in a variety of configurations to achieve a desired rotational or linear movement and force.

How Gear Shafts Work

Gear shafts rotate to enable one gear to engage and turn the teeth of another gear. Gears are used to transfer motion and torque between machine components in mechanical devices without slipping. If the gears in a system are of different sizes, they can be used to increase torque: The smaller wheel turns more quickly but with less force, while the bigger one turns more slowly with more force.

Types of Gears

There are many types of gears, the most common of which are below. Norca Precision experts will help you determine the most efficient gear / gear shaft solution for each application, promptly developing and delivering high-quality finished product.

Spur gears: The most common gear type, spur gears have straight teeth that sit parallel to the wheel’s axis and gear shaft. They have cylindrical pitch surfaces and can achieve high precision, without creating any load (thrust load) in the axial direction.

Spur gears: The most common gear type, spur gears have straight teeth that sit parallel to the wheel’s axis and gear shaft. They have cylindrical pitch surfaces and can achieve high precision, without creating any load (thrust load) in the axial direction. Helical gears: A helical, or spiral, gear is a cylindrical gear with twisted, screw-like teeth. Helical gears are used to transmit power between parallel or nonparallel gear shafts. Helical gears have tighter teeth meshing than spur gears, making them suitable for transmitting higher loads within high-speed applications. Helical gears, unlike spur gears, generate thrust along the gear’s axis; this must be accommodated for by thrust bearings.

Helical gears: A helical, or spiral, gear is a cylindrical gear with twisted, screw-like teeth. Helical gears are used to transmit power between parallel or nonparallel gear shafts. Helical gears have tighter teeth meshing than spur gears, making them suitable for transmitting higher loads within high-speed applications. Helical gears, unlike spur gears, generate thrust along the gear’s axis; this must be accommodated for by thrust bearings. Bevel gears: Bevel gears have tapered teeth and a conical shape. They are most commonly used to transmit force between two gear shafts that intersect at one point (this setup is called an ‘intersecting gear shaft’). Bevel gears come in a variety of profiles, including straight bevel, zerol bevel, spiral bevel, miter bevel and crown bevel gears.

Bevel gears: Bevel gears have tapered teeth and a conical shape. They are most commonly used to transmit force between two gear shafts that intersect at one point (this setup is called an ‘intersecting gear shaft’). Bevel gears come in a variety of profiles, including straight bevel, zerol bevel, spiral bevel, miter bevel and crown bevel gears. Crown gears: Crown gears are a special type of bevel gear in which the gear’s teeth project out at right angles to the plane of the wheel, looking like a crown. Crown gears typically work in gear systems with other bevel gears, but can be configured to work with simpler spur gears.

Crown gears: Crown gears are a special type of bevel gear in which the gear’s teeth project out at right angles to the plane of the wheel, looking like a crown. Crown gears typically work in gear systems with other bevel gears, but can be configured to work with simpler spur gears. Miter gears: A form of bevel gear, Miter gears have an equal number of teeth on both faces, and work with gear shafts that are at right angles to one another.

Miter gears: A form of bevel gear, Miter gears have an equal number of teeth on both faces, and work with gear shafts that are at right angles to one another. Worm gears: A worm gear is a special type of helical gear, in which the angle is large (close to 90 degrees) and the body length is long in the axial direction, such that it resembles a screw. Worm gear systems are a simple way to achieve a high torque, low speed gear ratio.

Worm gears: A worm gear is a special type of helical gear, in which the angle is large (close to 90 degrees) and the body length is long in the axial direction, such that it resembles a screw. Worm gear systems are a simple way to achieve a high torque, low speed gear ratio. Gear rack: Gear racks (also called ‘rack and pinion’ setup) are used to transform rotational motion into linear motion and vice versa. A gear rack setup consists of a cylindrical gear and a linear gear (the rack), which is typically a flat surface or a straight rod. Both gars have the same sized and shaped teeth cut at equal distances.

Gear rack: Gear racks (also called ‘rack and pinion’ setup) are used to transform rotational motion into linear motion and vice versa. A gear rack setup consists of a cylindrical gear and a linear gear (the rack), which is typically a flat surface or a straight rod. Both gars have the same sized and shaped teeth cut at equal distances. Hypoid gears: Hypoid gears are similar to spiral bevel gears except that their shaft axes do not intersect. Rather, Hypoid gears are usually designed to operate with shafts at 90 degrees. Depending on the configuration, contact between hypoid gear teeth may be even smoother than with spiral bevel gears.

Hypoid gears: Hypoid gears are similar to spiral bevel gears except that their shaft axes do not intersect. Rather, Hypoid gears are usually designed to operate with shafts at 90 degrees. Depending on the configuration, contact between hypoid gear teeth may be even smoother than with spiral bevel gears. External vs. Internal gears: The gears outlined above are external gears, with teeth placed on the outer surface of the cylindrical or conical gear. Internal gears are also available, in which the teeth sit on the inner surface of the gear.

External vs. Internal gears: The gears outlined above are external gears, with teeth placed on the outer surface of the cylindrical or conical gear. Internal gears are also available, in which the teeth sit on the inner surface of the gear.

Gear Shaft Configurations

A good way to think about types of gears and gear assemblies is to consider the configurations of the gear shafts to which they connect. At Norca, our gear shafts are designed for highly efficient motion controls and power transmission for any desired setup. We support all three types of gear shaft configurations:

- Parallel Axes: In this most common configuration, the gear shafts sit parallel to one another. Spur gears, helical gears, gear racks (rack and pinion) and internal gears all work with parallel gear shaft setups.

- Intersecting Axes: In this configuration, gear shaft axes intersect at a single point. Miter gears, straight bevel gears and spiral bevel gears work with this gear shaft setup

- Nonparallel, Nonintersecting Axes: As opposed to the two configurations above, this setup works with gear shaft that are at an angle to one another; in the case of a Worm gear, the angle is 90 degrees.

Whatever your high-performance gear shaft needs, we are here to help. Please contact us using the buttons below.

How Can We Help You?

Call (516) 467-0091

Or Fill Out The Form Below: